Make what matters™

3D PRINT INDUSTRIAL-STRENGTH ELASTOMERS ANYWHERE,

ON ANYTHING

ONE PART

OR ONE MILLION

Learn More About Our Advanced Elastomer Materials and 3D Printing Solutions

Delivering Advanced Elastomer Materials and 3D Printing Solutions

Stop imagining the world you want. Start making it.

See how our technology helped fashion designer Anouk Wipprecht create a new futuristic 3D-printed dress that responds to its environment through nearly 75 LEDs.

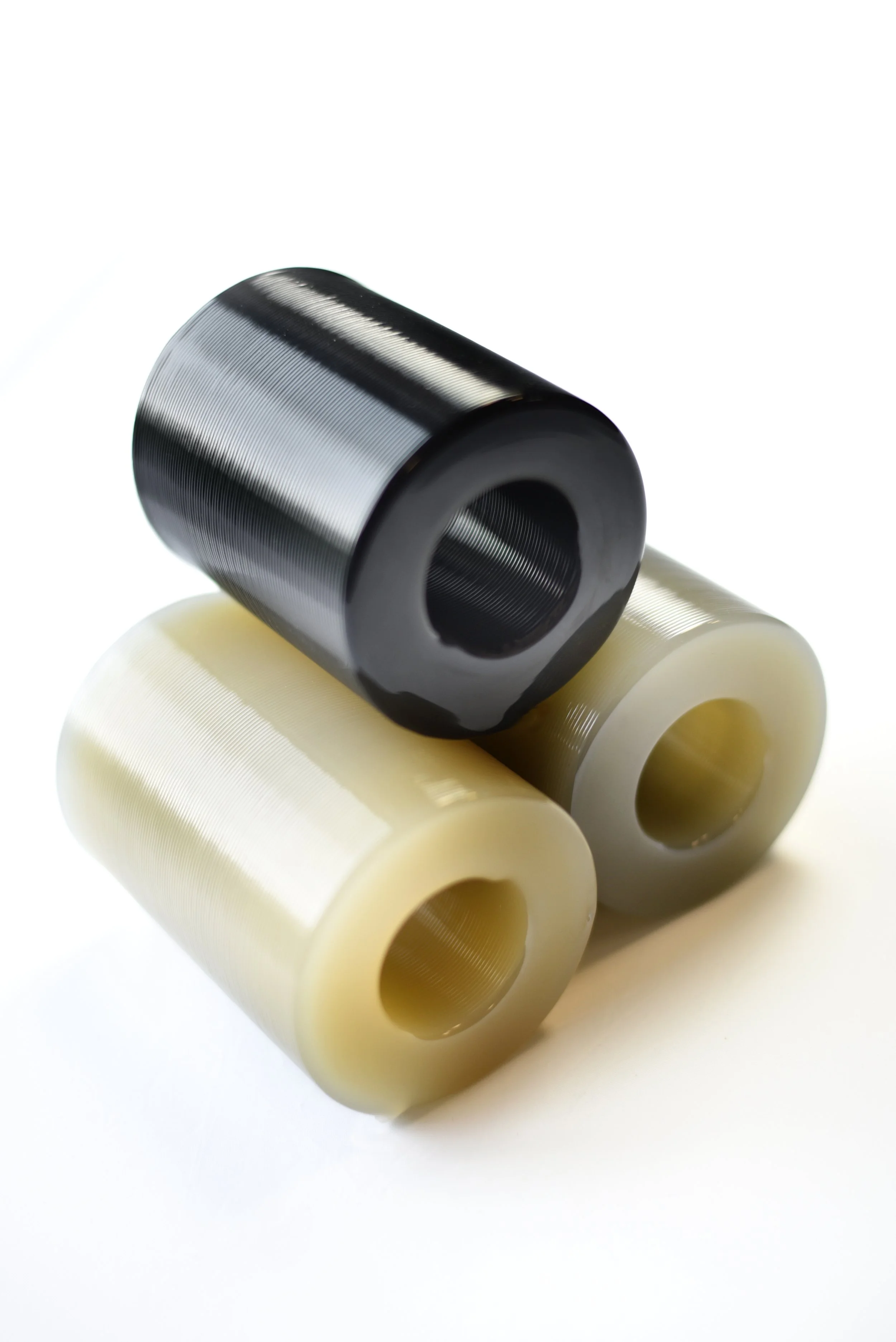

THE ADDITIVE MANUFACTURING PLATFORM FOR 3D PRINTING DURABLE RUBBER PARTS

RX-AM™ is the only materials and technology platform that lets you harness the power of chemical reactions to print industrial-strength elastomeric parts.

Get the durability you need with all the perks of additive manufacturing:

- control and flexibility

- lower total cost of ownership

- sustainability

Plus a world of radical new design options.

Introducing RX-AM™:

With the RX-AM™ platform, you can 3D print with chemical reactions. No melting, lasers or post processing.

Material cures

as it is deposited

Liquid materials flow

through the printhead

Our production-ready printing delivers a smooth result and allows unique geometries for novel product designs.

See what our technology can do

Flexible materials you know and trust

RX-AM™ makes it possible to print products with qualified materials you know and trust. Choose from our range of thermoset polyurethane elastomers in Shore A 50-90. Fully customize flexibility, strength and color. Or let us make your existing materials printable.

Our 3D printing technology is different

Buy 3D-printed polyurethane parts

In a rush? Let us print for you. Get common parts in custom dimensions delivered in days — with no tooling costs.

Not like other

additive manufacturing

With the RX-AM™ platform, you 3D print on any substrate for new, unconventional assemblies:

metal

textile

plastics

ceramics

Polyurethane printed directly on metal

Be the first to know.

Subscribe to our mailing list.